Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the world of construction, efficiency and quality are crucial. The Manual Block Machine stands out as a reliable tool. It offers various benefits that can enhance building projects. Using this machine can lead to significant improvements in production processes.

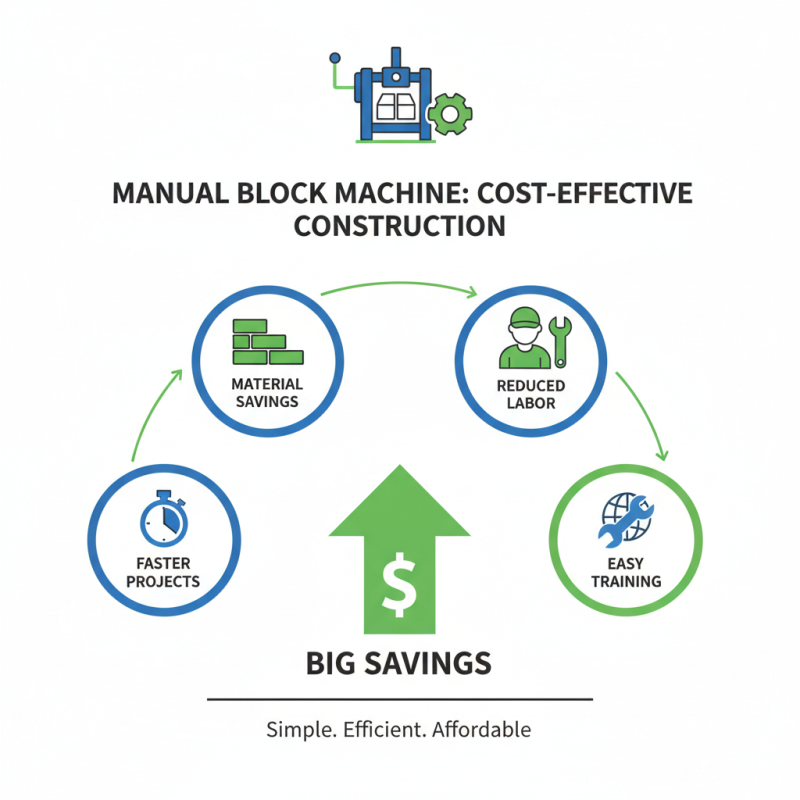

One key advantage of the Manual Block Machine is its cost-effectiveness. Unlike automated systems, the manual version requires less initial investment. This can be appealing for small businesses or new entrepreneurs. Moreover, it allows for precision in block production. Each block can be crafted to specific measurements, reducing waste.

User engagement is another benefit. Operating this machine requires hands-on skills, fostering a deeper understanding of the materials. However, it's important to reflect on the learning curve involved. Not everyone will find it easy at first. Despite this, the rewards of mastering the Manual Block Machine can be substantial. It encourages a blend of craftsmanship and productivity in construction.

When it comes to cost-effective construction, a manual block machine stands out. It allows for significant savings in materials and labor. Workers can operate the machine with minimal training, reducing the need for skilled labor. This is particularly useful in areas with limited access to professional manpower. Hours can be saved on each project, making it more efficient.

Additionally, the use of a manual block machine helps in producing quality blocks. Builders can adjust the density and size of the blocks as needed. This customization can lead to better thermal insulation and structural integrity. However, using a manual machine does have its drawbacks. The physical strain on workers can be noticeable over time. Maintaining consistent quality can also be challenging without proper oversight.

Moreover, while these machines are generally affordable, initial costs can still be a concern. Depending on the project size, the return on investment varies. Evaluating these factors early on can enhance overall project efficiency. A manual block machine can be a best choice for certain construction needs, yet requires careful consideration of its limitations.

Manual block machines offer significant advantages for construction projects. They enhance efficiency by allowing on-site production of blocks. This leads to reduced transportation costs and time delays. Workers can produce the exact number of blocks needed, minimizing waste. Having control over the materials ensures better quality and consistency.

These machines are straightforward to operate. Training workers can be done quickly. However, there are challenges. Initial setup might require time and effort. Manual block machines can also be labor-intensive, which may be a drawback in larger projects. Still, the hands-on approach fosters team collaboration. Workers often feel a sense of ownership and pride in their work.

While manual block machines might not replace larger automated options, they provide flexibility. They can adapt to various project sizes and requirements. However, over-reliance on manual processes can lead to inefficiencies. It’s crucial to find the right balance. With proper management, using manual block machines can be a smart choice for enhancing construction efficiency.

| Benefit | Description | Impact on Construction |

|---|---|---|

| Cost-Effectiveness | Manual block machines are generally less expensive to operate compared to automated machines. | Reduces overall project budget. |

| Simplicity of Operation | These machines are easier to operate, requiring less technical skill. | Lowers labor training costs. |

| Portability | Manual machines can be easily moved around the construction site. | Increases flexibility in project planning. |

| Energy Efficient | They operate without the need for electricity or fuel. | Reduces energy consumption and costs. |

| High Quality of Blocks | Produces dense and durable blocks with the right mixture. | Enhances the structural integrity of buildings. |

| Customization | Easily adjust the size and shape of blocks as needed. | Provides flexibility to meet project specifications. |

| Less Maintenance | Requires minimal maintenance compared to complex machinery. | Saves time and reduces downtime. |

| Reduced Waste | Efficient use of materials leads to less wastage. | Improves resource management. |

| Faster Production Times | Blocks can be produced quickly and in batches. | Speeds up construction timelines. |

| Eco-Friendly Option | Lower energy use and minimal plastic components help reduce environmental impact. | Promotes sustainable building practices. |

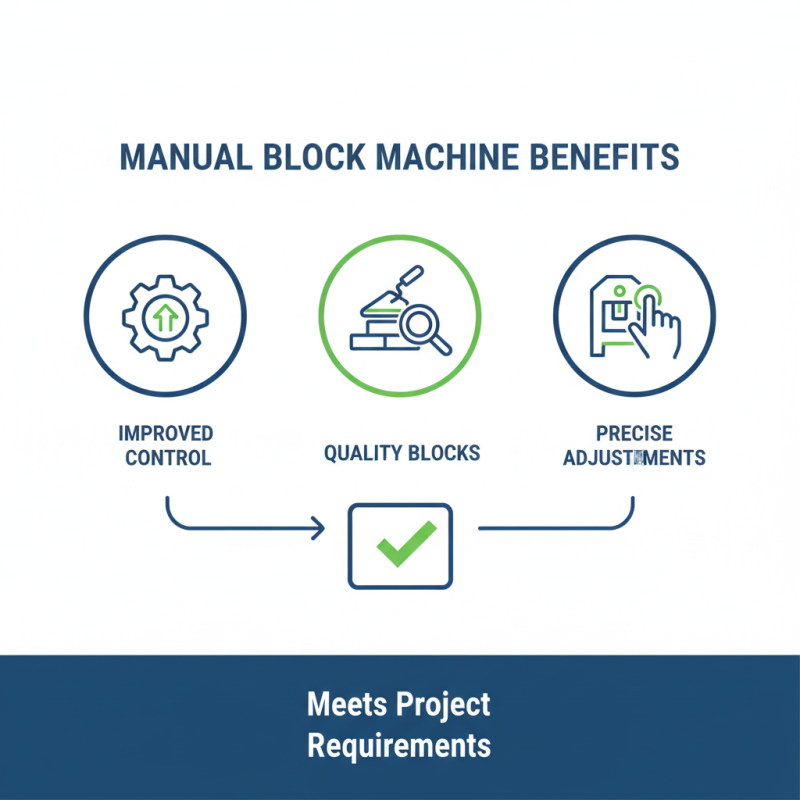

Using a manual block machine offers significant advantages for construction projects. One key benefit is improved control in block production. With manual operation, every detail can be adjusted precisely. Operators can monitor the consistency of materials, ensuring quality blocks that meet specific requirements. This level of oversight is often missing in automated systems.

Precision is crucial in construction. Manual machines allow for immediate adjustments during the production process. If a block doesn’t meet standards, it can be reworked on the spot. This hands-on approach minimizes waste and enhances overall productivity. A skilled operator can identify issues that machines might overlook, making the process more reliable.

While manual block production requires effort and skill, it has its challenges. Achieving the same output as automated systems can be difficult. Consistency also depends on the operator's experience. However, the benefits of control and precision often outweigh these drawbacks. In the hands of a dedicated worker, manual machines can produce high-quality blocks tailored to specific project needs.

The use of manual block machines in construction projects offers significant sustainability and environmental benefits. According to industry reports, manual methods can reduce energy consumption by up to 30% compared to automated alternatives. This reduction is crucial as construction contributes significantly to global carbon emissions.

Manual block machines often utilize locally sourced materials. This minimizes transportation emissions, which plays a vital role in reducing the overall carbon footprint. Additionally, they require minimal electricity, relying on human labor instead. This not only decreases energy usage but also promotes local job creation. However, one must consider that relying solely on manual techniques might slow down production rates in larger projects.

Tips: When using manual block machines, ensure your workforce is adequately trained. Investing in training can improve efficiency and safety. Assess your local materials for suitability. Sometimes, what you have nearby can be surprisingly effective. Always monitor energy consumption during operation, as even manual methods can have hidden energy costs.

The versatility of manual block machines makes them essential for various construction projects. These machines can create different types of blocks and bricks, suitable for both residential and commercial buildings. According to industry reports, the demand for sustainable construction methods has increased by 30% over the past five years. Manual machines provide an eco-friendly option that reduces waste and energy consumption.

In addition to creating standard blocks, these machines can adapt to specific project requirements. For instance, they can produce interlocking bricks, which enhance structural integrity. A study showed that using interlocking systems can reduce cement usage by up to 25%. However, operating a manual machine requires skilled labor. This can lead to variability in quality, which some projects may struggle to manage.

Another aspect worth noting is the low initial investment. Manual block machines are affordable and accessible. Yet, the cost savings come with trade-offs. Manual operation may slow down production compared to automatic machines. This discrepancy can affect timelines, especially in large-scale construction endeavors where speed is crucial. Balancing flexibility and efficiency remains a challenge for many builders.