Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the construction industry, efficiency is crucial. A Concrete Block Machine can significantly enhance productivity. Renowned expert John Smith once stated, "Investing in quality machinery is key for modern construction." His words resonate with many builders seeking better solutions.

Concrete Block Machines vary in specifications and capabilities. It's essential to choose the right one for specific needs. Some machines may promise high output but fall short in quality. A focus on the durability of blocks produced is vital.

Understanding the features of each machine is important. It helps in avoiding common pitfalls. While many machines offer advanced technology, they may require significant maintenance. Reflecting on these factors can lead to better investment decisions. Ultimately, the right Concrete Block Machine can transform a construction project.

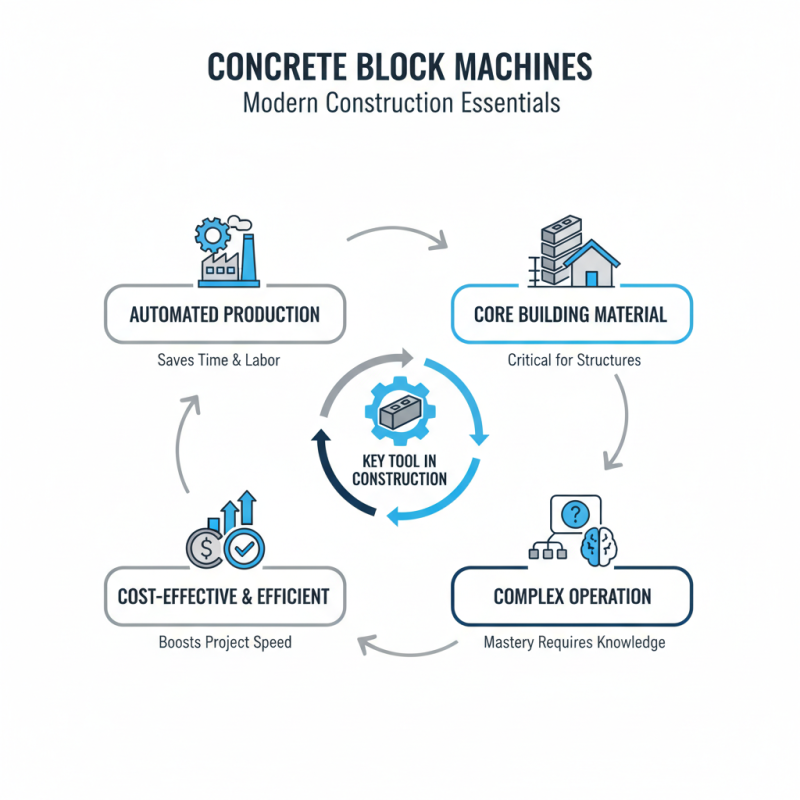

Concrete block machines are essential tools in modern construction. They are used to produce concrete blocks, which are critical for building structures. By automating the block-making process, these machines save time and labor costs. However, understanding their operation can be a bit challenging.

One key aspect of a concrete block machine is its design. Different machines have varying production capacities. Some produce blocks rapidly, while others may offer lower output yet provide more customization. This variability can impact the efficiency of a construction project. The user must assess the project requirements before choosing a machine.

Maintenance is another crucial factor to consider. Many operators overlook regular upkeep, leading to reduced performance. Dust accumulation can hinder machine functions, and worn parts can affect block quality. Being proactive in maintenance ensures consistent productivity. Investing time in understanding a machine's operation manual can make a significant difference. Ultimately, while these machines are beneficial, their effectiveness largely relies on the user's knowledge and diligence.

When choosing a concrete block machine, several key features come into play. Efficiency is critical, as it directly impacts your construction timeline. Look for machines that offer high production rates while maintaining quality. The machine should be capable of producing blocks consistently and quickly. This ensures that you keep up with your project schedule.

Consider the machine's capacity and size. Larger machines can produce more blocks, but they require more space. It's essential to balance space with production needs. Some machines are portable, which can be an advantage for smaller sites. Make sure the machine fits your specific requirements.

Tips: When selecting a machine, pay attention to energy consumption. Machines that use less energy can save you money long-term. Check for ease of operation. A user-friendly interface can save you time during setup and operation. Don't overlook the availability of spare parts. Maintenance can be a hassle without easy access to components. Choose wisely to avoid carrying excess burdens later.

In the competitive world of concrete block machines, selecting the right brand can greatly influence efficiency. Many manufacturers prioritize innovation and durability. Features like automatic brick making and high production capacity attract buyers' attention.

Companies often showcase robust designs that can withstand harsh conditions. However, it's important to consider the service network and parts availability. Not all brands offer the same support after the sale.

While leading brands are appreciated for their cutting-edge technology, some smaller players bring unique solutions to the market. They may cater to specific needs, offering custom features. However, potential buyers might overlook these options due to brand recognition bias.

It takes time to understand the diverse offerings in this space. Keeping an open mind and exploring various technologies is vital for achieving optimal results. The right machine can boost productivity, but it demands thoughtful research on available brands and their capabilities.

When it comes to choosing between manual and automatic concrete block machines, efficiency is key. Manual machines have a lower upfront cost. They are easy to operate and require no electricity. However, they offer consistent quality only with skilled labor. Data shows that labor costs can hit 25% of total production expenses. This highlights the potential savings with automatic options.

Automatic machines, while pricier, promise higher output. They can produce more blocks per hour without the need for constant supervision. Some models report an increase in output by up to 70%. This plays a crucial role in large-scale projects. Maintenance can be an issue, though. Automated systems can be complicated and costly to repair.

Interestingly, market reports indicate a growing preference for automation. Projects seeking to boost productivity often lean towards these machines. Yet, transitioning to automation requires workforce training. A study noted that 80% of users experienced a learning curve. Striking a balance between cost and efficiency remains a challenge for many in the industry.

Maintaining a concrete block machine is essential for longevity and efficiency. A recent industry report indicated that proper maintenance can increase the lifespan of machinery by up to 40%. Regular checks on components like the hydraulic system and the mixer are crucial. These parts wear down and can lead to costly repairs if neglected.

Operators often overlook simple tasks, such as cleaning debris from the machine. This buildup can impede performance and reduce output quality. Scheduled maintenance routines can prevent these issues. Experts recommend a daily inspection checklist to ensure all parts function correctly.

Changes in weather and exposure to elements also affect machinery. Humidity can rust metal components, while extreme temperatures can alter the mix’s consistency. Monitoring these factors helps avoid operational failures. Adopting a proactive maintenance culture can mitigate these risks. Many operators report feeling overwhelmed by maintenance tasks. However, consistent monitoring yields better results and saves time in the long run.

| Machine Model | Production Capacity (Blocks/Hour) | Power Requirement (kW) | Weight (kg) | Price Range (USD) | Maintenance Tips |

|---|---|---|---|---|---|

| Model A | 1000 | 5 | 1200 | 5,000 - 7,000 | Regular lubrication, daily cleaning |

| Model B | 1200 | 7 | 1350 | 6,000 - 8,000 | Check hydraulic systems regularly |

| Model C | 800 | 4 | 1100 | 4,500 - 6,500 | Inspect the mold for cracks |

| Model D | 1500 | 9 | 1500 | 7,500 - 9,500 | Ensure proper resetting of molds |

| Model E | 900 | 6 | 1300 | 5,500 - 7,500 | Clean the feeding system regularly |