Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the construction industry, the "Mud Bricks Machine" represents a transformative technology. These machines use local materials to produce eco-friendly building blocks. Expert John Greenfield notes, "Mud bricks are not only affordable; they are sustainable and efficient.”

Mud Brick Machines offer a practical solution in various regions. They can produce large quantities of bricks from soil, which reduces the need for expensive materials. However, mastering their operation requires skill and experience. Some users find it challenging to achieve consistent brick quality.

While they empower communities, reliance on technology raises questions. Are we bypassing traditional methods too quickly? Does this impact local craftsmanship? Such reflections can lead to better practices in the mud brick industry. Embracing innovation should not mean neglecting valuable skills and traditions.

Mud bricks are ancient building materials. They are made from clay, sand, and water. The mixture is then molded and dried in the sun. These natural bricks have been used for thousands of years. They are still relevant in today's construction. Their thermal mass makes them energy-efficient, keeping buildings cool in summer and warm in winter.

Using mud bricks has environmental benefits. They are biodegradable and require less energy than fired bricks. However, quality can vary greatly. Not all mud bricks are created equal. Some are too soft and crumble easily. Others may absorb too much water, leading to structural issues. Testing is essential to ensure durability and strength.

Mud bricks also hold cultural significance. Many regions have their unique techniques for crafting them. Those traditions should be respected and preserved. Sharing knowledge about mud bricks can foster community ties. While they represent simplicity, they also challenge modern construction practices. Balancing tradition with innovation can be tricky, but it can lead to sustainable growth.

Mud bricks machines play a crucial role in modern construction. They produce sustainable building materials using clay, sand, and water. This method reduces the carbon footprint significantly compared to conventional bricks. According to the International Energy Agency, the construction industry contributes to nearly 39% of global CO2 emissions. Thus, using mud bricks can support eco-friendly practices.

The purpose of a mud bricks machine is to automate the production process. It typically compresses the raw materials into molds, creating bricks quickly and efficiently. Research indicates that using these machines can increase production rates by up to 50%. This efficiency meets the growing demand for sustainable housing. However, operating these machines requires skill. Users must calibrate the machines for different soil types.

The technology remains imperfect. Some machines struggle with consistency in brick quality. Other challenges include machine maintenance and the need for skilled operators. As the industry advances, these issues need addressing for broader adoption. The journey towards sustainable construction is ongoing, and improvements are essential.

| Dimension | Description |

|---|---|

| Definition | A machine designed to manufacture mud bricks by compressing a mixture of soil, water, and other components. |

| Purpose | To provide an efficient means of producing eco-friendly building materials. |

| Materials Used | Soil, water, and natural additives such as straw or sand. |

| Process | Mixing soil and water, pressing the mixture to form bricks, and then curing the bricks. |

| Advantages | Sustainability, cost-effectiveness, and excellent thermal properties. |

| Applications | Used in construction for homes, schools, and eco-friendly buildings. |

Mud brick machines are innovative tools for producing sustainable building materials. Understanding their key components helps in optimizing their performance and outcome.

Mixing Chamber: One crucial part of a mud brick machine is the mixing chamber. This is where the raw materials are combined. The mixture typically includes soil, water, and a stabilizer. Properly mixing these elements is vital. It affects the strength of the bricks. If the mixture is too dry, bricks may crumble. Too wet, and they won’t hold shape.

Compressing Mechanism: Another key component is the compressing mechanism. This part shapes the bricks under high pressure. It determines the density and durability of the final product. If the compression is uneven, it leads to weak bricks. Therefore, monitoring this process is important.

Tip: Regularly check the moisture content of your materials. Adjusting it can lead to better brick quality.

Drying System: The drying system is also significant. After shaping, the bricks must dry properly. This process can be slow and influenced by weather. Rushing it can cause cracking. Observing the bricks during drying can prevent issues.

Tip: Consider using natural sunlight for drying, when possible. It is energy-efficient and can improve the bricks’ strength.

Optimizing each component is an ongoing journey. Experimenting with various soil types and mixtures may yield surprising results. Small changes lead to significant improvements in quality and sustainability.

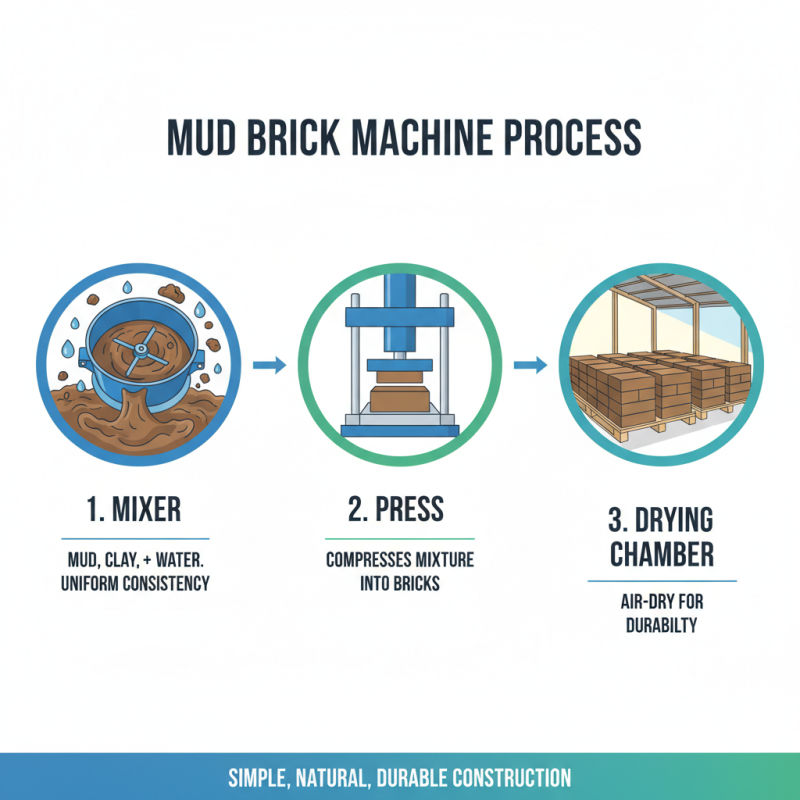

A mud bricks machine uses a simple yet effective process to create durable bricks from natural materials. The main components include a mixer, a press, and a drying chamber. It starts with mixing mud, clay, and water in the mixer. This mixture needs to be uniform, but achieving the right consistency can be tricky.

Once the mixture is ready, it’s fed into a brick press. The press shapes the mud into bricks. It applies significant pressure to ensure the bricks are compact and sturdy. This step requires careful calibration. If the pressure is too low, the bricks might crumble. If too high, they can crack. After pressing, the bricks must be dried properly. They are usually placed in a drying chamber with controlled humidity and temperature.

However, not every batch turns out perfect. Variations in moisture content can affect the final product. Sometimes, bricks may warp or not cure effectively. Operators need to adjust the process based on observations. This trial-and-error aspect is where experience becomes invaluable. Over time, it becomes easier to create consistent quality bricks.

Mud bricks machines offer several advantages in construction. They create sustainable building materials by compressing earth and stabilizers. This process uses local resources, reducing transport costs and carbon footprint. The resulting bricks are strong and have excellent thermal properties. They can keep homes cool in summer and warm in winter.

However, there are limitations to using these machines. The production process requires specific skills and knowledge. Not all operators may have the necessary training. Consistency in brick quality can vary, leading to structural issues. Additionally, mud bricks are vulnerable to moisture. Without proper protection, they may erode over time. Climate considerations should also be addressed, as extreme weather affects their performance.

Maintenance of the machines is crucial. Over time, wear and tear can impact efficiency. Inconsistent maintenance leads to unpredictable outputs. Challenges like this require ongoing reflection and improvement. Investing in skill development and proper training can mitigate many of these issues. Building awareness about the properties of mud bricks is equally important. This helps users understand when they are the right choice.