Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In recent years, the demand for sustainable construction methods has surged, paving the way for the widespread use of the Interlocking Block Machine. According to a report by the Global Construction Index, the adoption of interlocking blocks is projected to grow by 15% annually through 2026. This technology allows for efficient and eco-friendly building solutions. The Interlocking Block Machine creates blocks that require no mortar, thus reducing waste and construction time.

Expert in the field, Dr. Mark Thompson, emphasizes, “The Interlocking Block Machine offers a revolutionary approach to construction.” His insights reflect a growing industry trend towards cost-efficient and environmentally responsible building practices. However, challenges remain. Users must ensure proper training and maintenance to maximize the machine's efficiency. Improper handling may lead to subpar block quality, affecting structural integrity.

In conclusion, understanding how to use an Interlocking Block Machine effectively is crucial. The potential for high-quality construction exists, but it requires attention to detail and a commitment to best practices. Investing in this technology can yield significant benefits, but also demands continuous improvement and learning.

Interlocking block machines play a significant role in modern construction. These machines create blocks that fit together without the need for mortar. Understanding their functionality is key for effective use. They can produce various sizes and shapes of blocks, making them versatile for builders. The process usually involves mixing raw materials, compressing them, and curing them in a controlled environment.

Tips for using interlocking block machines effectively: Ensure that your mixture has the right consistency. Too dry or too wet can lead to weak blocks. Regular maintenance of the machine is crucial. Clean the mold and check for wear and tear regularly. Misalignment may occur, leading to uneven blocks. This requires a keen eye to adjust the setup.

Another vital aspect is training. Operators should undergo proper training. Understanding the machine's controls and settings can prevent common mistakes. Even small errors can lead to block failure. Be prepared to adapt your technique based on the results. Trial and error can help refine your process. The reliability of the blocks produced heavily depends on how well these machines are operated.

| Feature | Description | Benefits | Usage Tips |

|---|---|---|---|

| Machine Type | Hydraulic or Manual | Adaptability to different projects | Choose based on project scale |

| Block Size | Customizable dimensions | Flexibility in design layout | Determine size based on structural needs |

| Material Compatibility | Cement, clay, or recycled materials | Eco-friendly options available | Test materials for best results |

| Mold Quality | Durable and precise molds | Consistent block production | Inspect and maintain molds regularly |

| Operating Procedure | Step-by-step guidelines | Efficiency in production | Follow manuals and training |

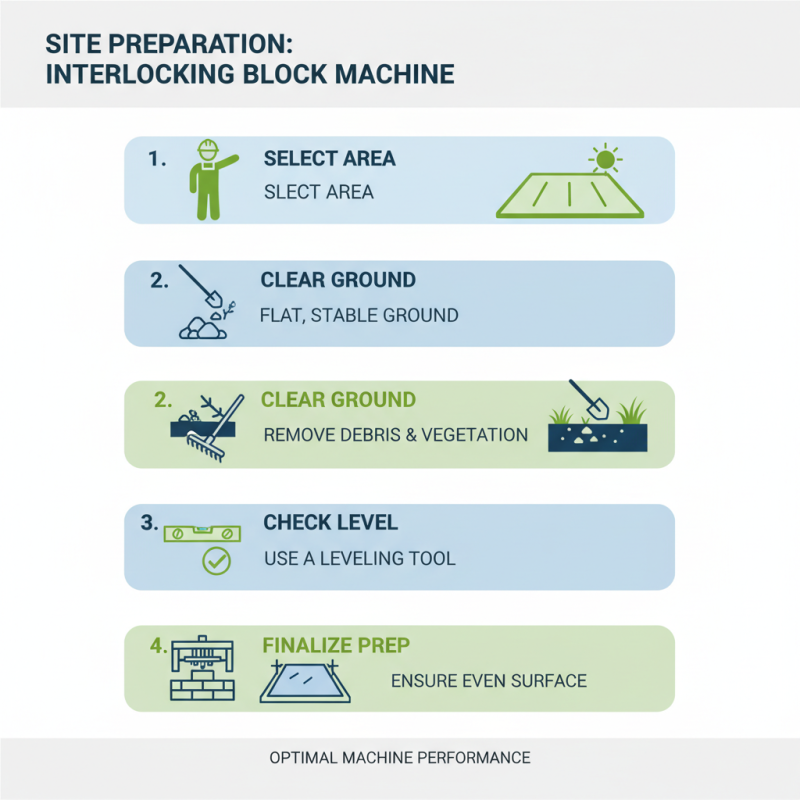

Preparing the site for an interlocking block machine is crucial. Start by selecting a flat, stable area. Remove any debris or vegetation. Uneven ground can lead to operational issues. Use a level to check the surface. If it's not flat, additional site preparation may be necessary.

Next, ensure there is adequate drainage. Standing water can damage the machine and the blocks produced. Create slopes away from the work area. Compact the soil or gravel if needed. This method reduces settling over time. Areas with heavy rainfall might require extra precautions.

Consider access points for material delivery. Too much congestion can slow down the workflow. Reflecting on space usage can improve efficiency. A designated zone for raw materials will help maintain order. Remember, a well-prepared site saves time and enhances productivity.

When producing interlocking blocks, selecting the right materials is crucial. The quality of materials can influence the durability of the blocks. Common materials include cement, aggregates, and water. Ensure that aggregates are clean and free from contaminants. Use well-graded aggregates to enhance the block's strength.

Consider these tips for material selection. First, test the moisture content of sand and aggregates. Excess moisture can weaken the final product. Second, always use high-quality cement. It should be stored properly to prevent clumping. Remember, low-quality cement can lead to poor interlocking blocks.

Lastly, reflect on the local environment. Sometimes, local materials may not meet quality standards. In such cases, you might face challenges. Balancing cost and quality is essential. Family-run businesses often use cheaper, lower-quality materials. This can cause issues in the long run. Always evaluate the trade-offs before making decisions.

Operating an interlocking block machine requires precision and care. Each step significantly impacts the final product's quality. Properly preparing the materials is crucial. The right mix of sand, cement, and additives can enhance durability. Studies show that a well-mixed batch can increase block strength by 30%. Inadequate mixing leads to structural weaknesses.

Loading the machine with materials is another critical step. Ensure the hopper is clean and free from debris. A jammed hopper can disrupt production and affect block consistency. Many operators overlook this simple step, which can result in costly downtime. Furthermore, the machine's settings should match the type of blocks being produced. Calibration errors might lead to blocks of varying sizes.

Monitoring the curing process is essential for block quality. Improper curing can reduce the block’s lifespan. Reports indicate that blocks cured at optimal temperatures have a 25% higher resistance to wear. Regular checks on temperature and humidity levels are beneficial. Neglecting this aspect can cause unexpected failures. Reflecting on these points helps in maintaining a smooth operation. Every detail matters in achieving excellent results.

To ensure the longevity and efficiency of an interlocking block machine, regular maintenance is key. Start by checking hydraulic fluid levels. This fluid is vital for smooth operation and should be replenished as needed. Clean the machine daily to prevent dirt buildup. Dust and debris can cause parts to wear out faster. Regularly inspect all moving parts for signs of wear. Replace any damaged components immediately to avoid larger issues.

Next, focus on lubrication. Keep mechanical parts well-lubricated to reduce friction. This will extend the life of the machine. Use the right type of lubricant as specified in the operating manual. Be mindful of the machine's operating environment. Extreme temperatures can affect performance. Consider climate impacts and schedule maintenance accordingly.

Additionally, train all operators on proper usage. Misuse can lead to excessive wear or malfunction. Regular training sessions can enhance operator skills. Reflect on any recurring problems. Are they due to lack of maintenance? Identifying these issues is crucial for improving efficiency. Taking proactive steps will ensure the machine runs well for years.