Cement Pole Making Machine - A Powerful Tool for Efficient Cement Pole Production

In the contemporary construction industry, the Cement Pole Making Machine holds an irreplaceable position. Whether it is the construction of urban power grids, the layout of rural communication lines, or the support of street lamps on both sides of roads, cement poles, as key building materials, rely on this equipment for efficient production.

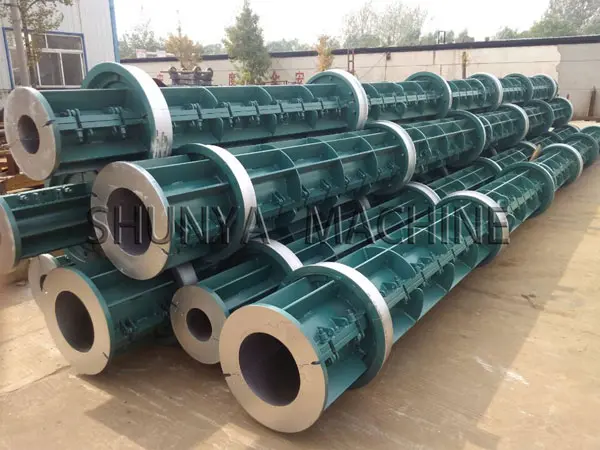

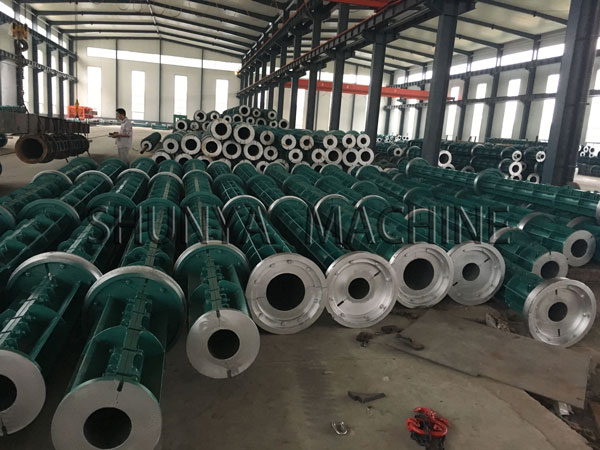

In terms of working mechanism, the Cement Pole Making Machine has a scientific and rigorous process. Firstly, in the material preparation stage, the precise metering system will accurately send cement, sand, crushed stones, water, and appropriate additives into the mixing and stirring device according to the preset proportions. This stage has extremely high requirements for the accuracy of raw material input, and any deviation may affect the quality of the final product. The fully stirred and uniform concrete slurry will be injected into the specially made molds. The shape and size of the molds can be completely customized according to actual needs, and they can easily adapt to common circular, square, or special - specification cement poles. Inside the molds, after high - frequency vibration or pressure compaction treatment, the concrete slurry has a tight internal structure and thorough bubble removal, thus ensuring that the cement poles have high strength and density, meeting the strict quality standards of various projects.

The advantages of this equipment are very prominent. In terms of production efficiency, the automated production process has significantly shortened the production cycle. Compared with traditional methods, it can produce a large number of cement poles in a shorter time and reduce the input of labor costs. Quality stability is also a major feature. The scientific process and precise molds effectively avoid human operation errors, ensuring that each cement pole reaches a consistent high quality. In terms of versatility, the produced cement poles can be cut into different lengths according to project requirements, with a very wide range of applications. In terms of maintenance, its structural design is simple and reasonable, facilitating daily inspection and troubleshooting, extending the service life of the equipment, and reducing the use cost. In addition, the Cement Pole Making Machine adopts advanced energy - saving technologies, reducing energy consumption and environmental pollution during production, which is in line with the current concepts of green environmental protection and sustainable development.

With the continuous advancement of the construction industry and infrastructure development, the demand for cement poles is constantly growing and the requirements are becoming more stringent. The Cement Pole Making Machine, relying on its excellent performance, stable quality, and energy - saving and environmental protection advantages, will continue to play an important role in the market, provide strong support for the development of the construction industry, and help build a more solid, convenient, and green modern living environment.