Efficient Cement Pole Production Expert - Cement Pole Machine

In the fields of construction and power infrastructure construction, cement poles, as important supporting components, have a huge demand. Cement Pole Machine has become a powerful assistant in pole production with its excellent performance.

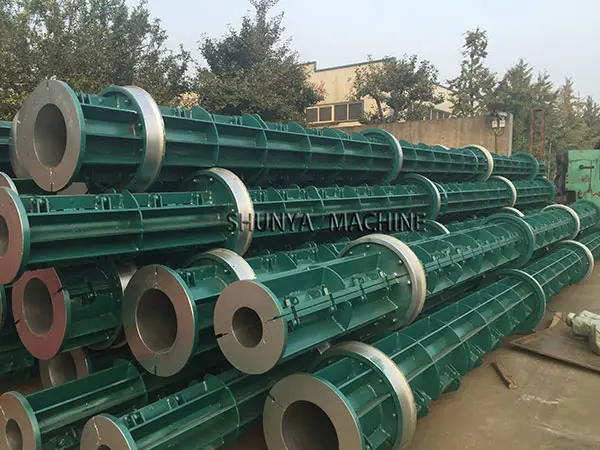

In terms of working principle, Cement Pole Machine first sends cement, sand, stones, water and additives into the mixing device in scientific proportions through an accurate metering system. The high - speed rotating mixing blades fully blend various raw materials to form a uniform concrete slurry, ensuring the stable quality of the poles. Then, the mixed slurry is poured into a carefully designed mold. The mold is customized according to different pole specifications with extremely high precision, ensuring the accurate shape and size of the poles. Subsequently, the mold enters the centrifugal stage. Under the action of the centrifugal force generated by high - speed rotation, the concrete slurry is evenly distributed and tightly compacted, expelling internal air bubbles and significantly improving the density and strength of the poles. Finally, after a specific time of steam curing, the concrete is fully hardened, and a high - quality cement pole is born.

Cement Pole Machine has many advantages. Firstly, it features high - efficiency production. The automated production process greatly shortens the production cycle. Compared with traditional production methods, the output can be greatly increased, effectively meeting the large - scale demand for poles in the market. Secondly, the quality is stable and reliable. Precise material proportioning and advanced production processes ensure that each pole meets strict quality standards and performs excellently in terms of bending resistance and compression resistance, and can adapt to various harsh environments. Moreover, the equipment is easy to operate. Workers can become proficient in operation after simple training, reducing labor costs and operation difficulties. In addition, it has good flexibility. It can quickly adjust production parameters according to different engineering requirements and produce poles with different lengths, diameters and strength grades.

In terms of application, Cement Pole Machine is widely used in the construction of temporary support structures in building construction, the laying of power transmission line poles, and the manufacturing of support facilities in fields such as communication base stations and street lighting. Whether it is urban construction or rural infrastructure improvement, the poles produced by it can be seen playing an important role.

With the continuous progress of technology, Cement Pole Machine is also continuously being upgraded and optimized. In the future, it will develop towards a more intelligent and energy - saving direction, contributing more to infrastructure construction.