Efficient Electric Pole Making Machine

The Electric Pole Making Machine stands as a cornerstone in the infrastructure equipment industry, engineered to streamline the production of concrete electric poles—critical components for power grids, telecommunication networks, and urban lighting systems.

Core Functionality & Technology

At its core, the machine utilizes centrifugal molding or vibration casting technology, depending on model, to achieve high-density concrete structures. This ensures poles withstand harsh weather, heavy loads, and long-term outdoor exposure. The integration of PLC control systems allows for precise regulation of rotation speed (for centrifugal models) or vibration frequency (for vibration models), eliminating air bubbles and ensuring uniform concrete distribution.

User-Friendly & Automated

Automation is a key highlight. From concrete feeding to mold clamping and demolding, the process requires minimal human intervention, reducing labor costs and error rates. Operators can preset parameters via a touchscreen interface, with real-time monitoring of pressure, temperature, and cycle time. Safety features such as emergency stop buttons and overload protection further enhance operational security.

Durability & Cost-Effectiveness

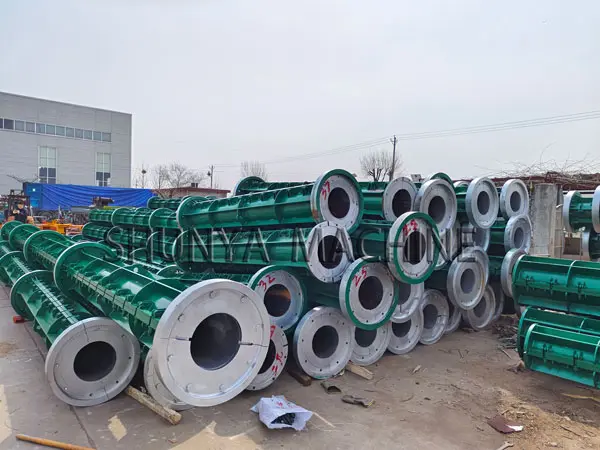

Constructed with high-strength alloy steel, the machine’s frame and molds resist wear and corrosion, ensuring a service life of 10+ years with proper maintenance. Molds are interchangeable, allowing quick switches between pole types without extensive retooling. Low energy consumption (typically 3-5kW/h per pole) and reduced material waste (thanks to precise concrete dosage control) lower long-term operational costs.

Application Scenarios

It caters to diverse sectors: power utilities rely on it for transmission pole production; telecom companies use it for 5G tower support poles; and municipal governments utilize it for street lighting and traffic signal poles. Its portability (some models feature wheels for on-site use) also benefits remote construction sites.

Why Choose It?

In an era of rapid urbanization, the Electric Pole Making Machine offers a blend of speed, precision, and reliability. It meets international standards (e.g., ASTM, BS) for concrete strength, ensuring poles pass load and durability tests. Manufacturers often provide customization options, such as adding steam curing systems for faster concrete setting, making it adaptable to regional climate conditions.

For businesses seeking to scale their infrastructure production, this machine is an investment that delivers consistent quality, reduces lead times, and enhances competitiveness in the growing construction and utility markets.