SY4-10 Large-scale Fully Automatic Hydraulic Clay Brick Equipment

Product details page content section:

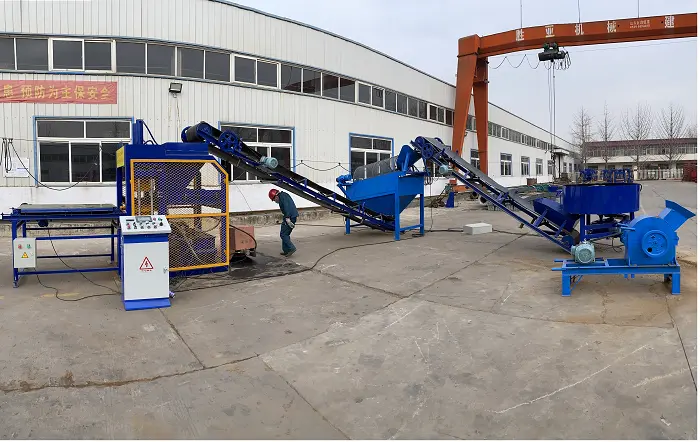

Industrial-grade Clay Brick Production Line

SY4-10 has transcended the concept of a single machine and is a complete fully automated industrial production system. It is composed of main pressing machine, automatic batching system, dual-track transfer manipulator, chain conveyor, and stacker-carrying device modules, forming a seamless production loop. This system is specifically designed to meet continuous large-scale orders, aiming to minimize human intervention through extreme automation, thereby achieving large-scale output and absolute uniform product quality, and defining new industry standards.

Superb Pressure, Ultimate Capacity

The core competitiveness of SY4-10 lies in its astonishing output capacity and overpowering pressure. Its heavy-duty hydraulic station can provide several times the pressure of smaller models, enabling the brick blanks to achieve nearly perfect density and strength, significantly reducing cracking and deformation during the subsequent drying process. The massive frame and customized molds are specifically designed for continuous 24-hour operation, ensuring long-term stability under high-speed production rates. The daily output is sufficient to support the material supply for large-scale projects.

Technical Specifications and Parameters

The performance of this model is guaranteed by a series of precise technical parameters, providing customers with clear investment references. The specific core parameters are as follows: The rated working pressure is as high as 16 MPa, ensuring the final molding quality. Each cycle can produce 4 standard-sized (such as 350*150*100mm) interlocking bricks, with excellent production efficiency. The main motor power is 7.5 kW, the hydraulic system operates stably, and the energy consumption is economical. The equipment's external dimensions (length × width × height) are approximately 1750 × 1350 × 2380 mm. The structure is reasonable, facilitating installation and layout. The total machine weight is about 2.5 tons. It uses sturdy steel and castings to ensure the durability and reliability of the equipment during long-term high-load operation. In addition, the equipment is equipped with advanced vibration and pressurization devices, making the internal structure of the bricks denser and the surface smoother, completely solving the pain points of traditional bricks being prone to breakage and wear.