SY7-10 hydraulic automatic clay block making machine

Product details page content section:

Product description

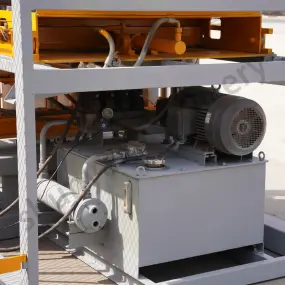

The machine incorporates advanced hydraulic technology, delivering pressure up to 60 MPa to ensure high density, strength, and consistent quality of blocks. Its four-guide-post structure ensures stable mold movement during operation.

Equipped with a PLC control system and proportional valves, it allows precise pressure adjustment via a user-friendly touch screen. The upper and lower oil cylinders press simultaneously to enhance brick strength. The machine also features a plunger pump and proportional valves for doubled pressure capacity. All molds are manufactured using precision wire cutting and carburizing heat treatment to extend service life. Built with thick steel and specialized welding techniques, the machine offers robust durability. Operating with a 100–120 ton hydraulic press, it guarantees the production of high-strength interlocking bricks and pavers.

Technical feature

Fully automatic hydraulic adobe brick making machines integrate advanced hydraulic systems and intelligent control technology to deliver high efficiency, consistency, and versatility in block production. They ensure high-density, precision-formed bricks with excellent surface quality and structural strength through powerful and stable compression. Capable of producing various types of bricks—including interlocking, hollow, and paving blocks—by simply changing molds, these machines significantly reduce manual operation, lower labor costs, and maintain continuous high output with minimal energy consumption. Ideal for both large factories and medium-sized projects, they offer durability, ease of maintenance, and rapid production cycles, providing users with reliable performance and long-term economic benefits.